Overview

A few years ago, a very interesting article on TechCentralStation.com entitled Send it, and We'll Figure Out How to Use It appeared. This article was about how military personnel are using scavanged and improvised hardware to help them when they are on the battlefield. Alot of the ideas in this article are very clever and should be looked into further.

Excerpt from "Send it, and We'll Figure Out How to Use It":

Glass Ceramics

Good old Corningware bowls bounce off concrete, but its ballistic resistance pales in comparison to the tougher stuff that glass makers transform into well named hard discs for computer memory drives. Cheap and readily manufactured, such materials approach the fracture toughness per unit weight of honest to gosh armor ceramics. Adding cesium to the precursor melt beefs up the computer grades, and mass production -- we're talking stovetops and windowpanes here -- can turn them out faster than silicon or boron carbide.

Scrap Kevlar Cloth

Any kind of aramid -- twaron, Kevlar, Whatever -- and almost any high tenacity fiber webbing or scrim, from Spectra to Nomex, are vast improvements on the lack of it for those with time and glue on their hands to reinforce their motley improvisations.

Apparently, the coatings on hard drive platters make them ideal for use as very light-weight improvised armor plating. These could be useful for protection against the metal shrapnel used in most Improvised Explosive Devices (IED) or suicide bombers belts. I doubt these will stop a 7.62x39 mm round, though. Also useful in battle, are scraps of Kevlar material. These are often "thrown away" daily in the form of cut or heat resistant mechanics gloves, Goodyear "SilentArmor" automobile tires, or even some high-performance bicycle tires (the kind that are puncture resistant). These all contain bits of Kevlar material which can be utilized as patches for real or improvised armor.

Kevlar XL Mechanic's Gloves (Harbor Freight Tools #92173) & Goodyear Fortera SUV Tires

Pictures & Notes

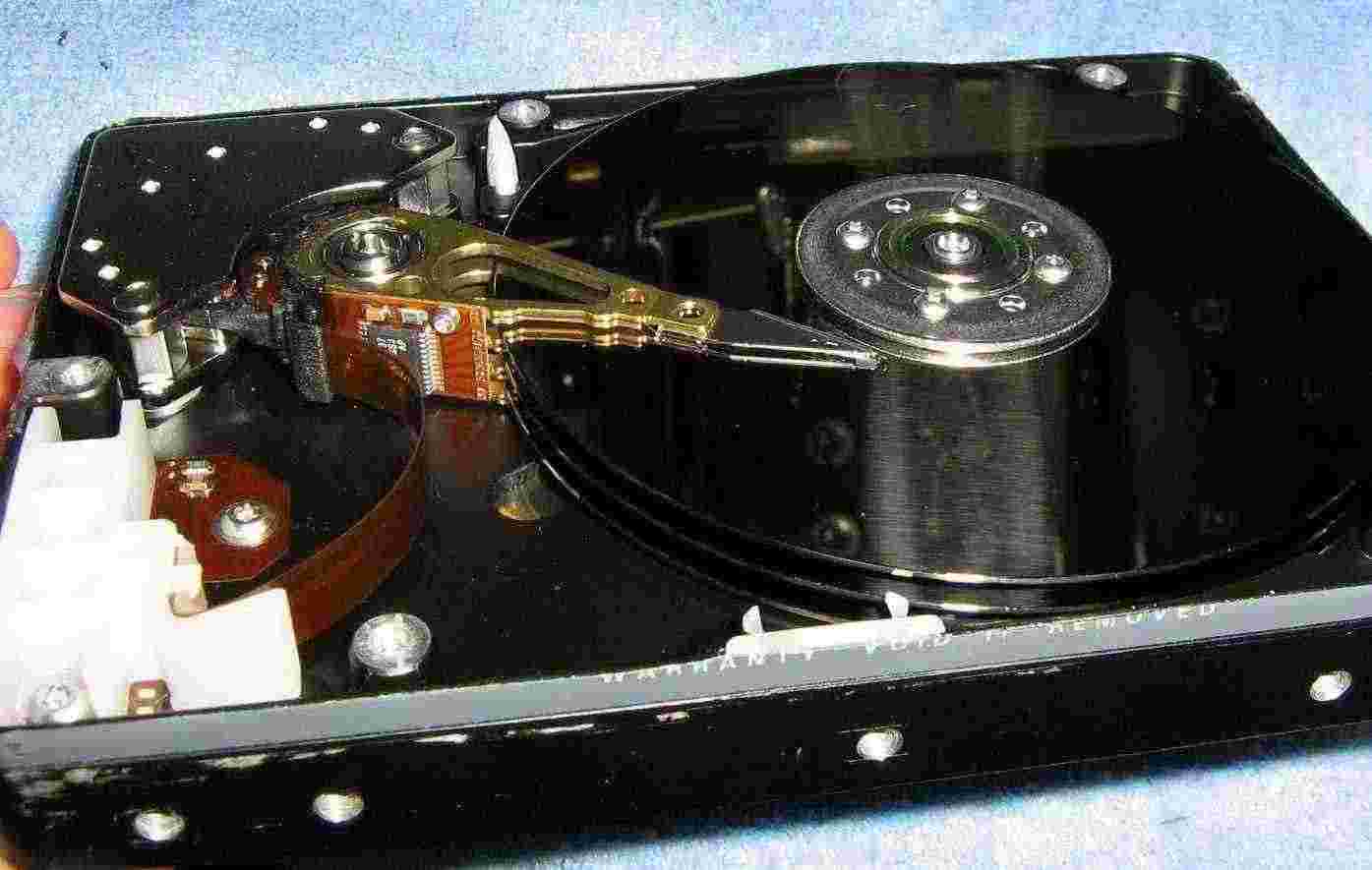

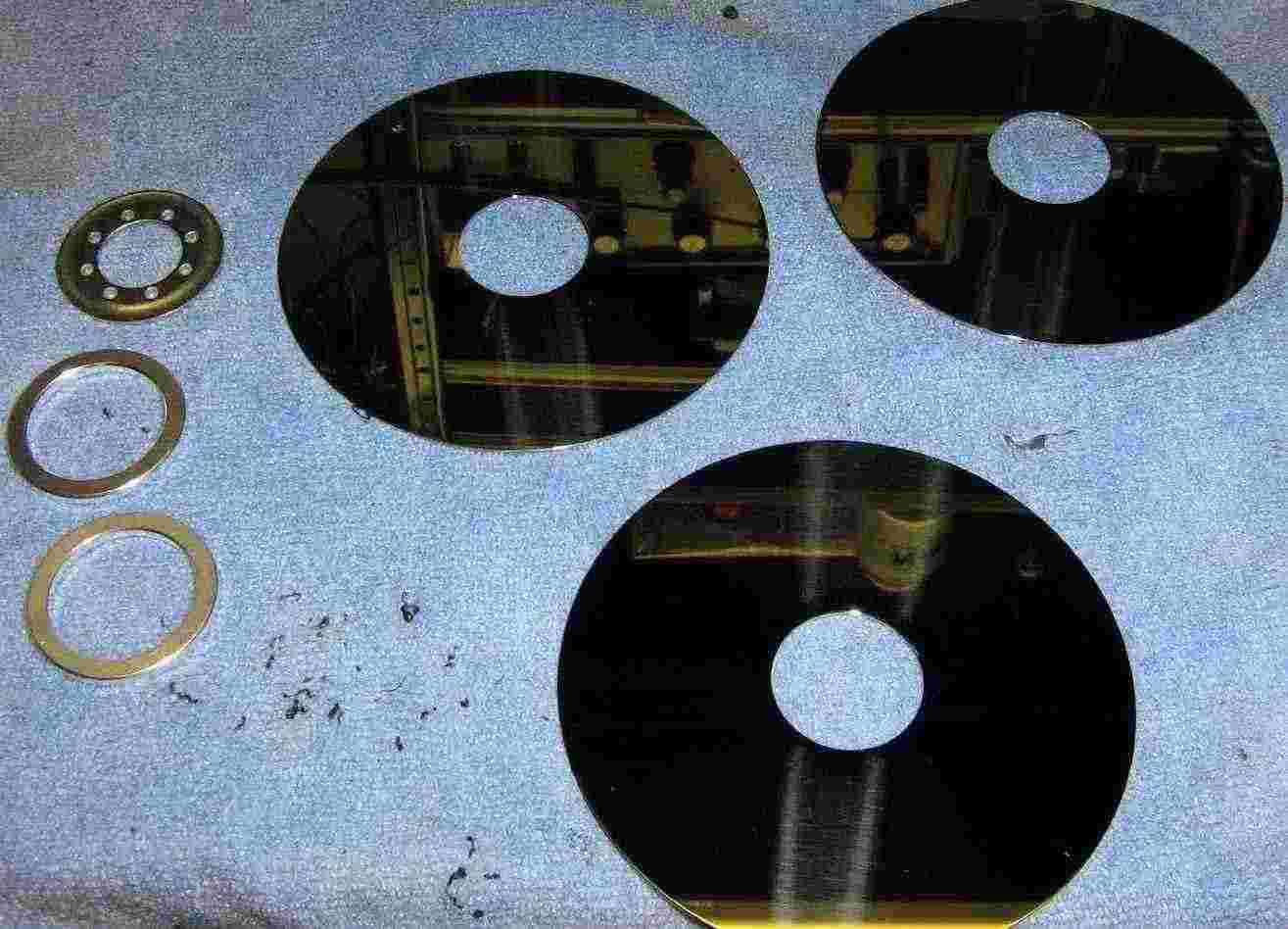

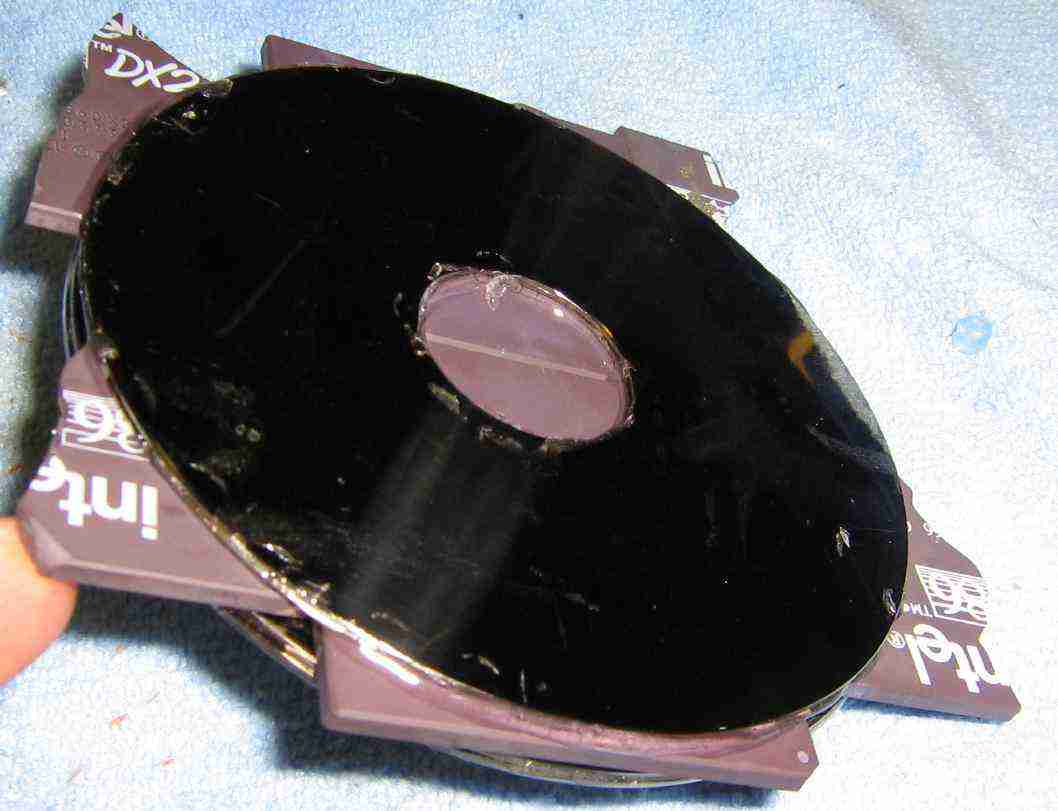

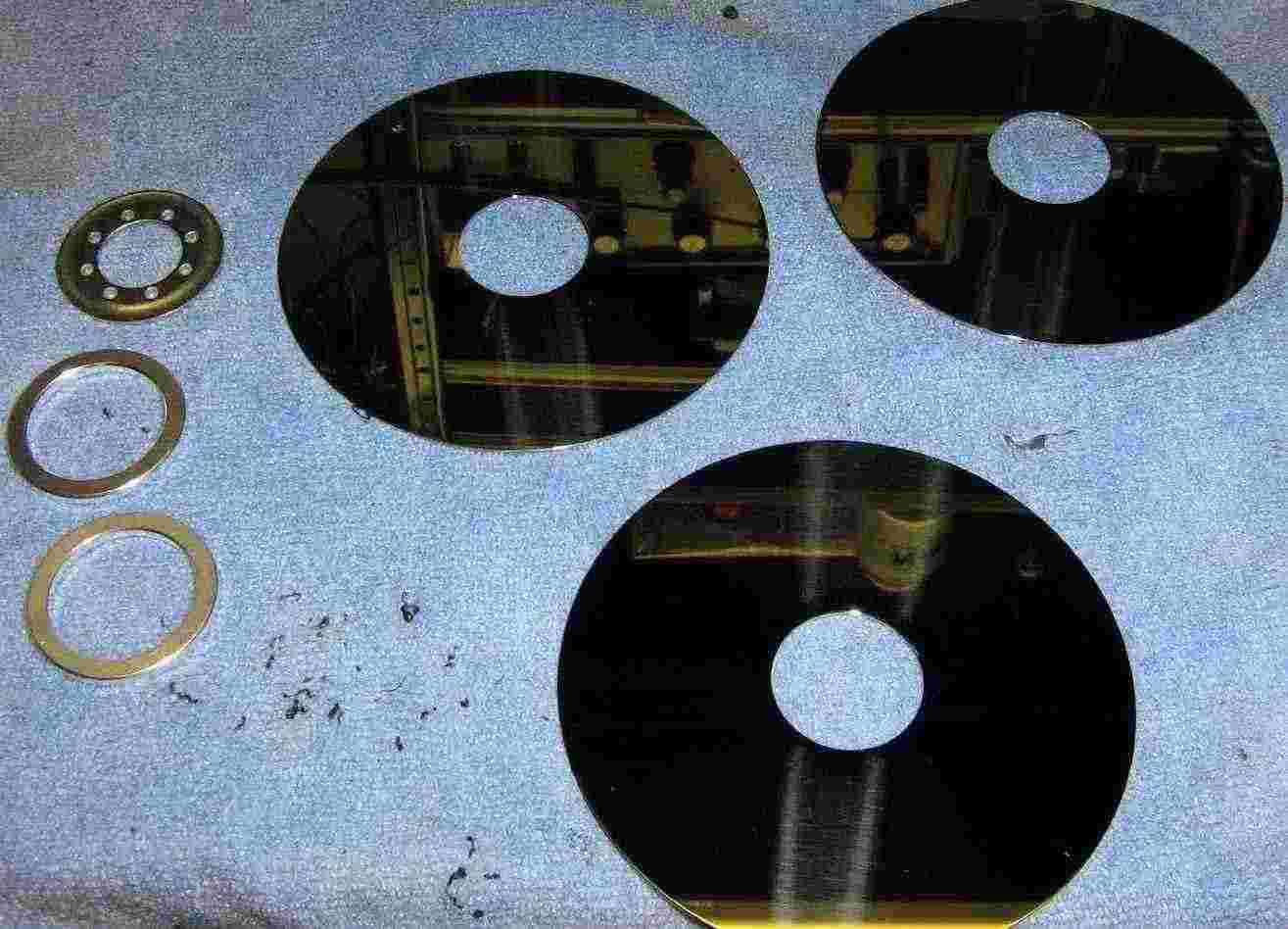

The two old hard drives used for this experiment. There may be a large difference in platter size and strength between manufacturers. I have no idea.

Take the hard drives apart using Torx screwdrivers and an X-acto knife. Save the controller PC board as it is a good source of surface mount components.

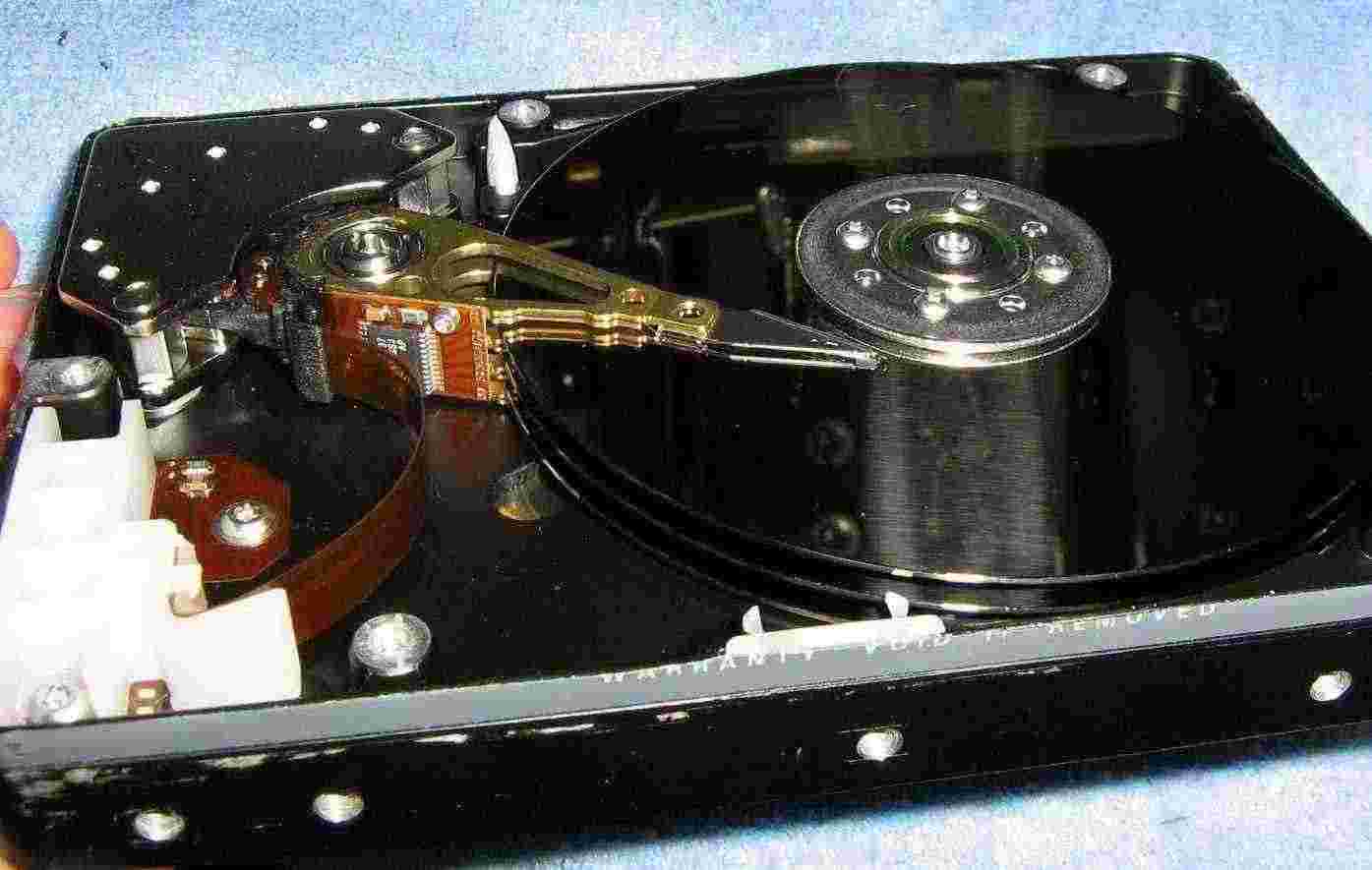

Hard drive internal view.

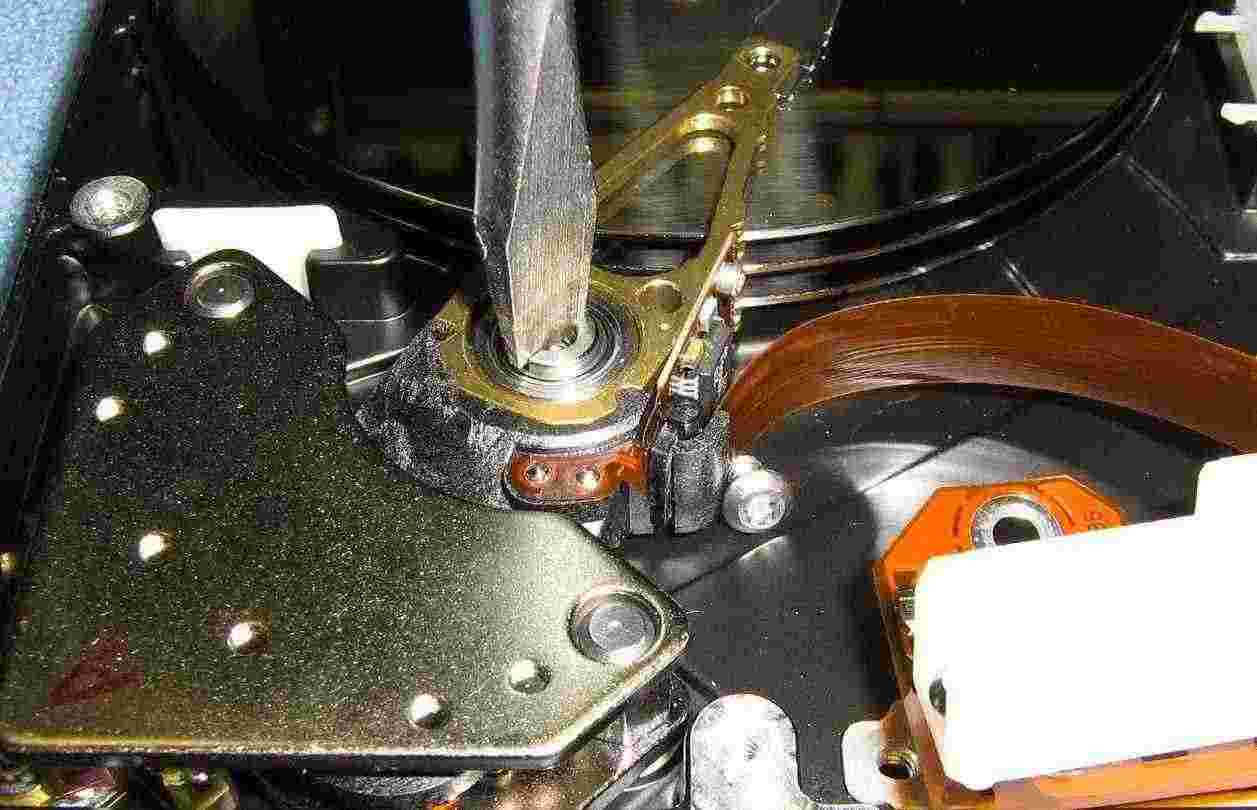

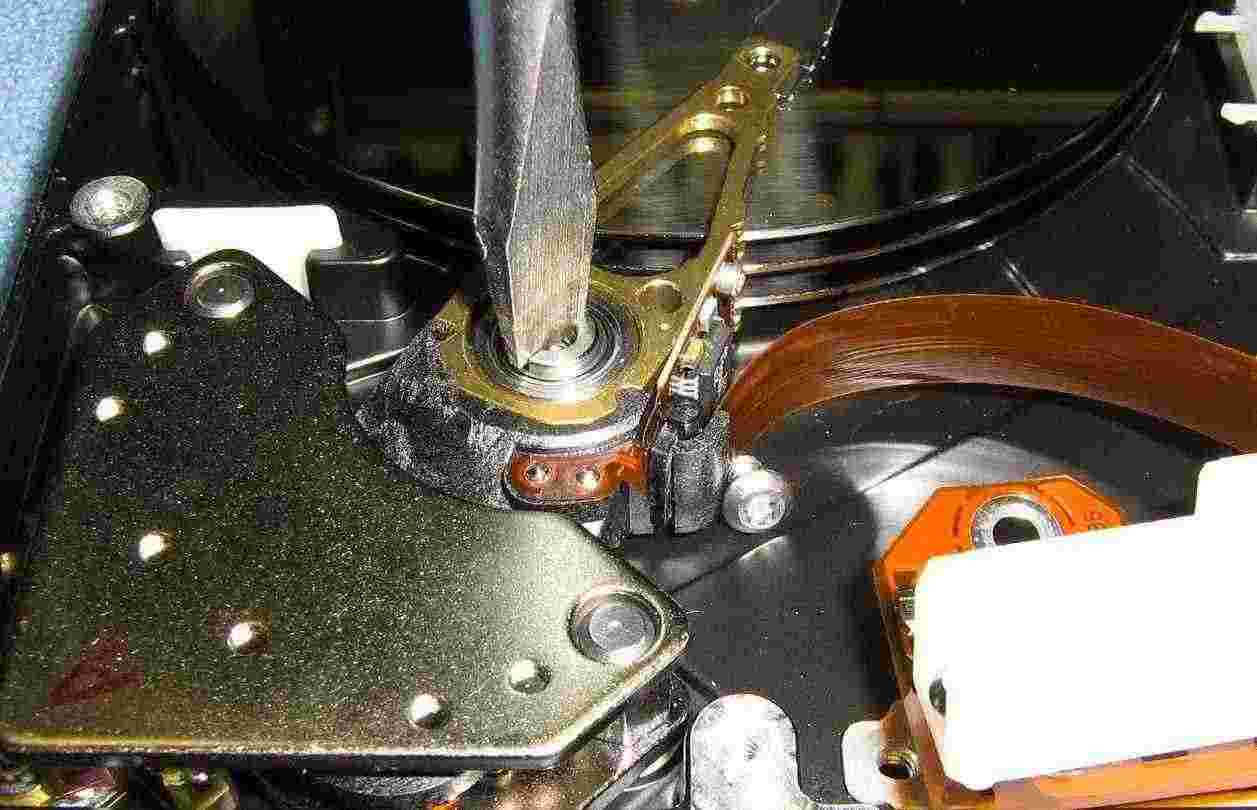

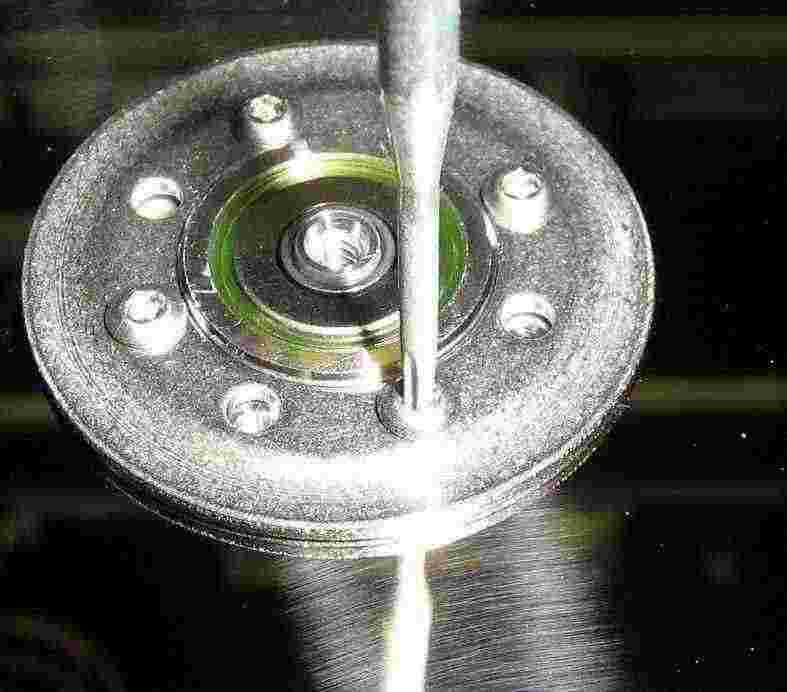

Remove the armature for the drive's magnetic head using a regular screwdriver as shown above.

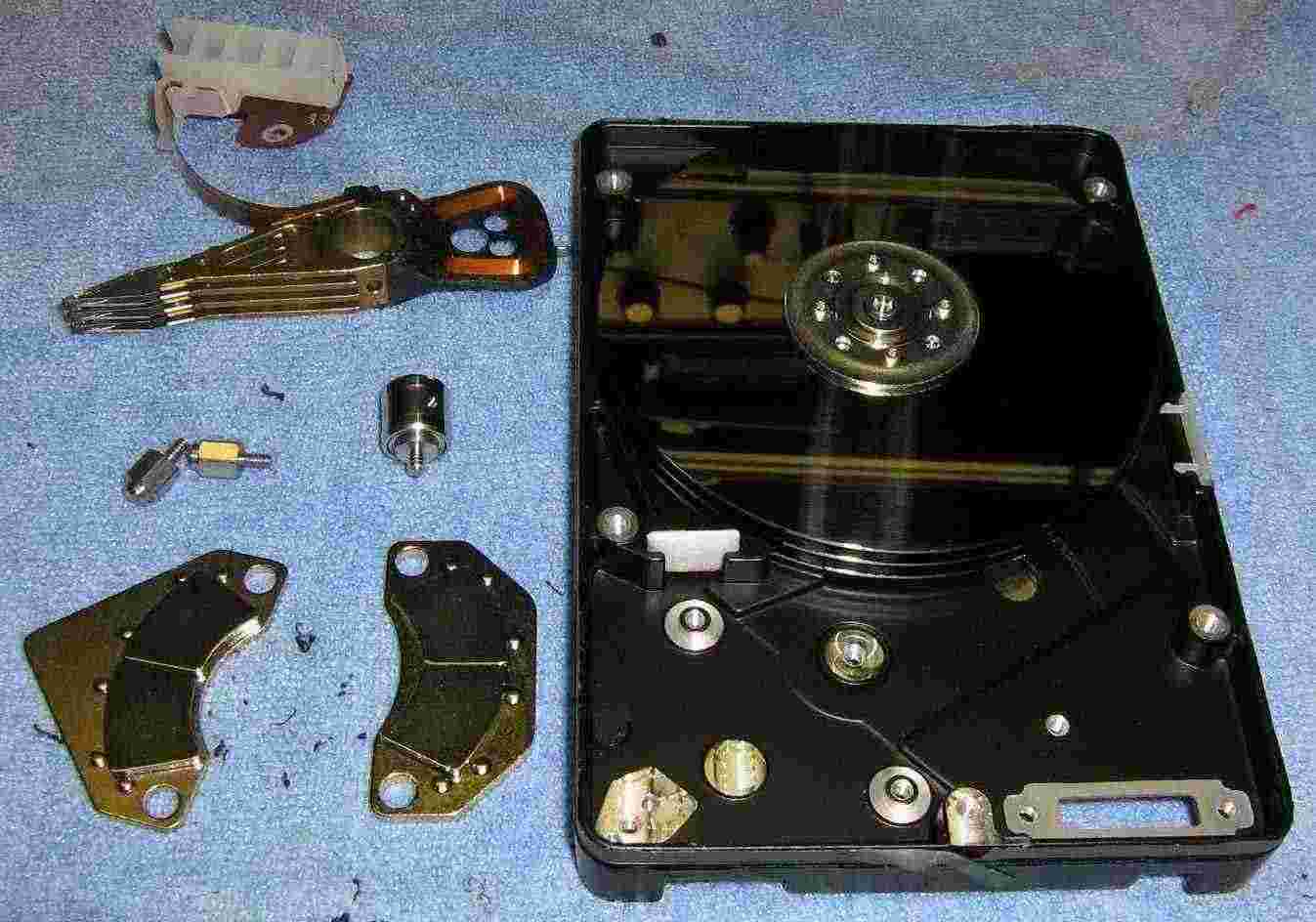

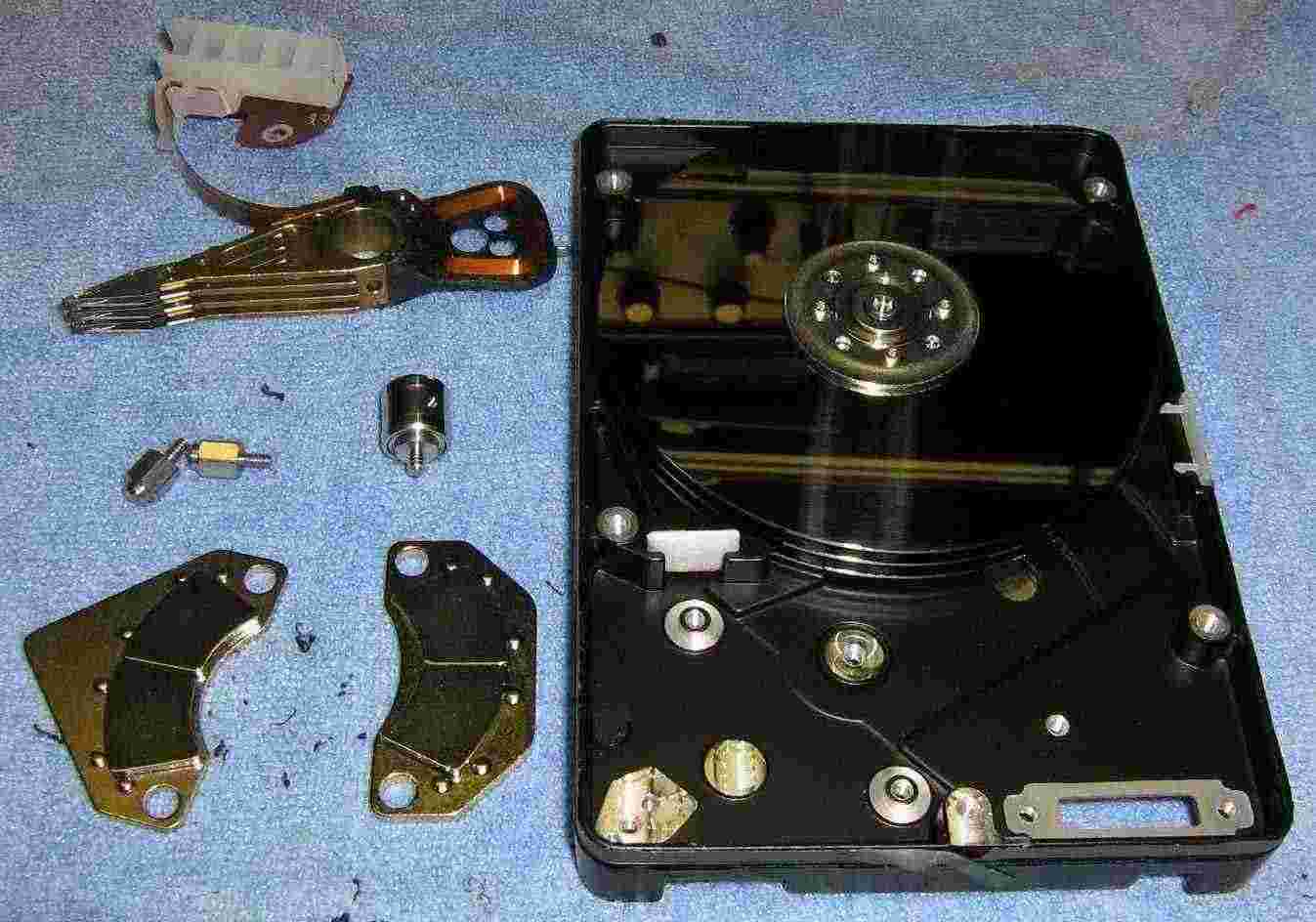

Remove the rest of the mechanical pieces. The magnets on the lower-left are very powerful and can be useful in other projects.

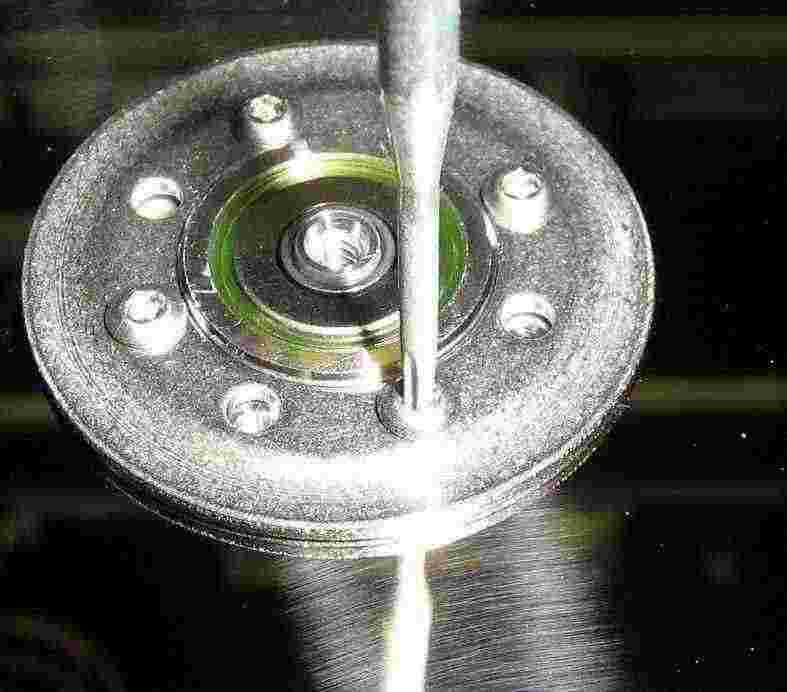

Remove the plate which holds the drive's platters down. This is usually a small #6 Torx screw.

Then remove the individual platters. There are usually two or three platters in each hard drive.

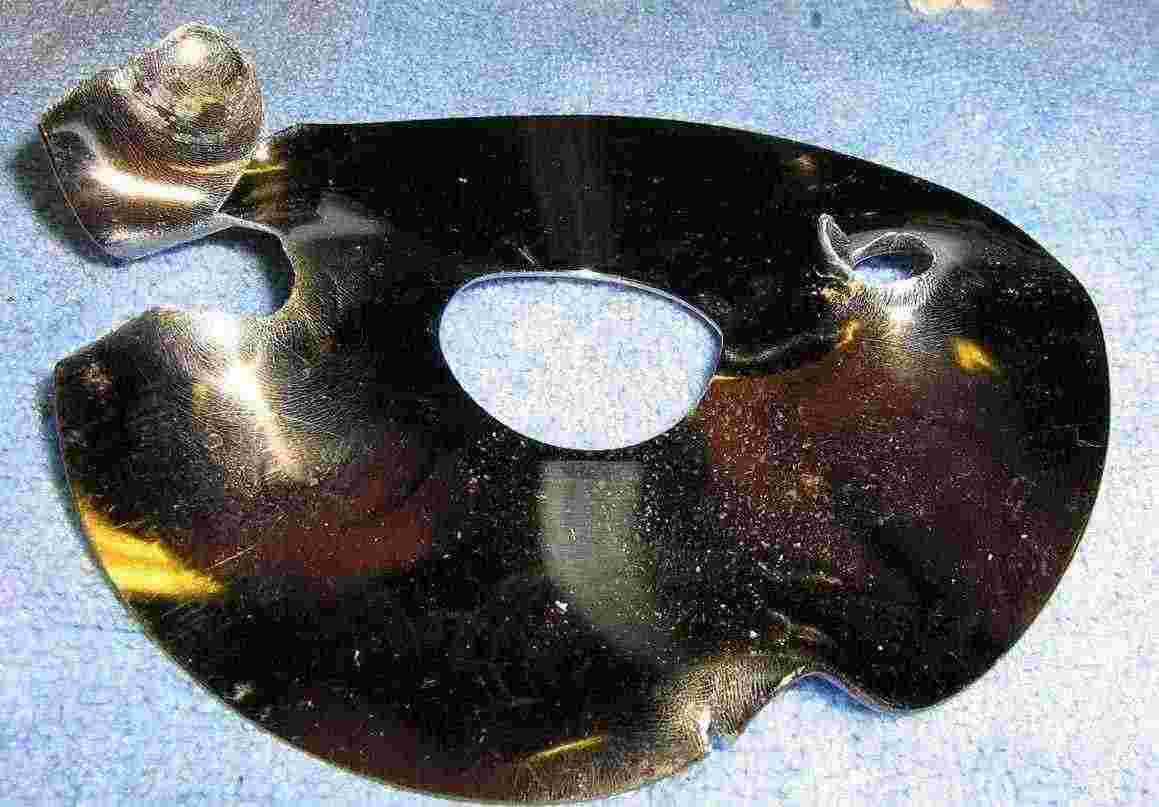

Initial strength test using a ball peen hammer. The individual drive platters appear to be very light (0.5 oz) aluminum discs with some sort of coating. Maybe it's the coating that gives them strength?

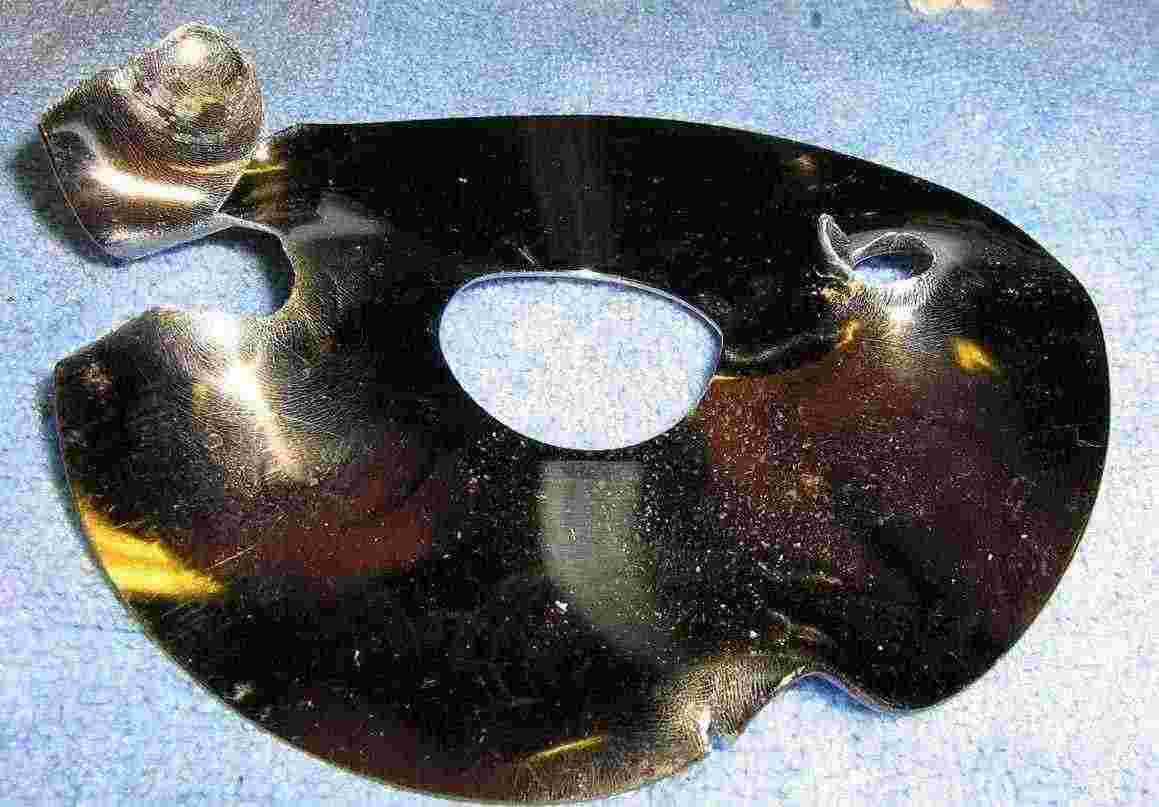

Close up of a hammer hit on a single disk platter.

Some of the two-part epoxy resins and putties used for this test. Use the epoxy resin (left) to sandwich two disk platters together for greater strength, then use the epoxy putty to hold the improvised armor in the location you need.

Spread the epoxy resin out along one of the platters.

Then clamp another one on top of it. Let it cure for at least five minutes.

Here are three sandwiched dual-platters epoxied together. Each one overlaps, covering the center hole on the platters underneath it.

Then place them inside a Kevlar lined mechanics glove for added protection from shrapnel and fire burns.

Real World Testing

Single hard drive platter. .45 Colt 200 grain lead ball (8.3 grains Unique) on the left, .22 LR (Remington Thunderbolt) on the right.

All shots were from Ruger revolvers at 20 feet. The idea was to simulate shrapnel. All the epoxy bonds broke when hit.

Dual hard drive platters epoxied together - .45 Colt exit.

Dual hard drive platters epoxied together - .22 LR. Stopped completely.

Rear view of the stopped .22 LR shot.

A different set of dual hard drive platters epoxied together - .22 LR with the same results.

A different test with the dual hard drive platters behind a pair of heavy leather gloves - .45 Colt went straight through. The idea is that thick leather can be used to reduce or even prevent any flesh burns from IEDs.

Exit wounds.

Dual hard drive platter combination close up. Exits.

The heavy leather gloves and dual hard drive platter combination could catch the .22 LR bullets.

Send it, and We'll Figure Out How to Use It

December 21, 2004 - From: www.techcentralstation.com

By Russell Seitz

What could a soldier in Iraq possibly do with a slab of armor plate or bulletproof glass? More than a defense procurement bureaucrat in Washington; hence the wise words of General De Long, USMC, Ret. on MSNBC last week: "Send it, and we'll figure out how to use it."

He was expressing the wisdom of military experience going back to the day Ugh the Grunt discovered his trusty jade ax; besides braining cave bears, could deflect the flint spears tossed by his irascible Neanderthal neighbors.

Soon this Neolithic genius studded a mammoth hide with clamshells, and composite armor was born. Within a hundred generations, Ugh's descendants were pinching Saigon man hole covers to put under their helicopter seats, and complaining to Congressmen about late flak armor deliveries. Today, plus ca change,

Middle America has a heartening tendency to actually do things for troops in the field. When grunts wrote home noting it was 140 degrees inside their tents, but that the Revolution In Military Affairs provided them with electricity to power tactical laptops, good people mobbed Walmart's to send $99 air conditioners to the nation's sons and daughters using one of the DOD's Really Good Things : The APO . It delivers parcels, even those containing air conditioners, to war zones with FedEx speed at 4th Class prices.

So what could Santa deliver to good kids spending the holidays under fire?

The stores are bare of humvee armor kits, or this essay would be pointless. Having already exhorted the Beltway denizens to twist the arms of the Scrooges managing our stay-at-home Euroallies' arsenals, here are a few thoughts on the right stuff to fill Kevlar stockings in record time. They range from off the shelf -- or out of the scrapyard -- to industrial processes whose speed takes precedence over economy.

Hillbilly Electronic Countermeasures

The Islamists' latest attempt to blow up Pakistan's president with roadside explosives ran afoul of a handy gadget called a VIP2 Road Ranger -- an electronic jammer that keeps radio controlled bombs from being triggered while their intended target is within lethal range. The Pentagon may pay about ten grand for gold-plated Mil Spec models, but the free market price of the same technology is closer to a microwave oven -- or a gray-market traffic radar jammer.

Used Tires

Not just any ones, and not the whole donut. What's needed is a program to round up and skive off the Kevlar belts that rim the nation's mountains of balding aircraft radials. This would spare our landfills while affording ingenious Gunnies a prime raw material for spanning hard to fit gaps in improvised explosion shields.

Glass Ceramics

Good old Corningware bowls bounce off concrete, but its ballistic resistance pales in comparison to the tougher stuff that glass makers transform into well named hard discs for computer memory drives. Cheap and readily manufactured, such materials approach the fracture toughness per unit weight of honest to gosh armor ceramics. Adding cesium to the precursor melt beefs up the computer grades, and mass production -- we're talking stovetops and windowpanes here -- can turn them out faster than silicon or boron carbide.

Scrap Kevlar Cloth

Any kind of aramid -- twaron, Kevlar, Whatever -- and almost any high tenacity fiber webbing or scrim, from Spectra to Nomex, are vast improvements on the lack of it for those with time and glue on their hands to reinforce their motley improvisations.

Adhesives

Duct tape kills. If you want to save a lot of lives for a little money, fast, investing it in seriously good epoxies and elastomers with energy absorbing fillers like microballoons is a highly portable way to go. If I sent one thing to Iraq, it would be high tenacity ways and means of enhancing the bonding of the catch as catch can vehicle armor people in theater improvise.

Small Halon Fire Extinguishers

The kind you can no longer buy, because they are hell on the ozone layer. So are third degree burns on human skin. If you've got 'em, in your closet or kitchen, send 'em, They are needed and they work so well that I would not want to be the DA who tries invoking the Montreal Convention to keep them out of vehicles going in harm's way.

Improvised Hardplate Armor

As a followup to an article on improvised armor, this idea is based on using old Ceramic Dual In-Line Package (CERDIP) integrated circuits, and even some old computer CPUs, as "hardplate" armor. The idea is that the hard ceramics which are used for the cases on these integrated circuits, can also be used to deflect any incoming shrapnel. Does it really work? I have no idea on how to test this stuff in the real world... But, it is fun to mess around with. The hard, but brittle, ceramic cases to tend to break into a million little pieces on impact. This might be good, as it is dissipating energy, but on the other hand, you are making even more shrapnel.

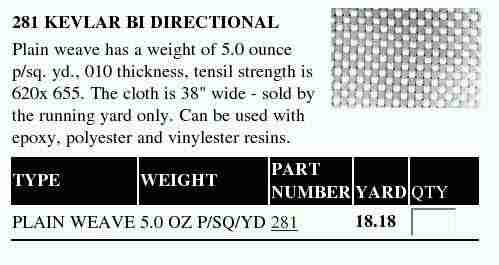

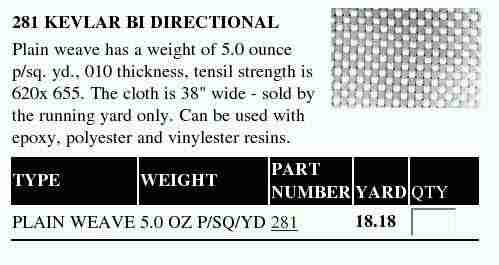

It would probably be a good idea to wrap this entire contraption in several (hundred?) layers of Kevlar material. A good source for large rolls of Kevlar material is from homebrew aircraft suppliers. The Kevlar material does appear to need a special set of shears to cut through it, though. Wicks Aircraft Supply, www.wicksaircraft.com, sells different types of Kelvar material at around $18 per yard:

Excerpt from a Wicks Aircraft Supply catalog:

Aramid fiber, one of the newest and most far-reaching developments of textile research, has the highest strength-to-weight ratio of any commercially available fiber. Kevlar gives airplane builders a significant design edge by allowing designers and builders to save weight and increase strength in their aircraft. Kevlar aramid has an excellent combination of weight, high-strength, outstanding toughness with abuse resistance, and stiffness, that can be put to good use in the production of light aircraft. Kevlar fibers have a density 43% lower than fiberglass and 23% to 30% lower than the various graphite and carbon fibers. Kevlar 49 is 2.5 times as strong as the commercially used E-glass and greater than ten times as strong as aluminum on a specific tensile strength basis. Kevlar has good chemical resistance and meets FAA flammability requirements as it does not melt or support combustion. It provides a less rigid structure, with even better damage resistance. Composites of Kevlar are more durable than those of fiberglass and carbon because the aramid fiber provides superior resistance to damage, vibration, and crack propagations, as well as excellent fatigue resistance. Although Kevlar has many advantages over conventional fiberglass weaves, it is very difficult to cut. Special scissors have been developed to facilitate cutting. These scissors have a wear-resistant coating which is metallurgically bonded to the steel substrate. The coating will not chip or peel off and can be sharpened.

Pictures & Notes

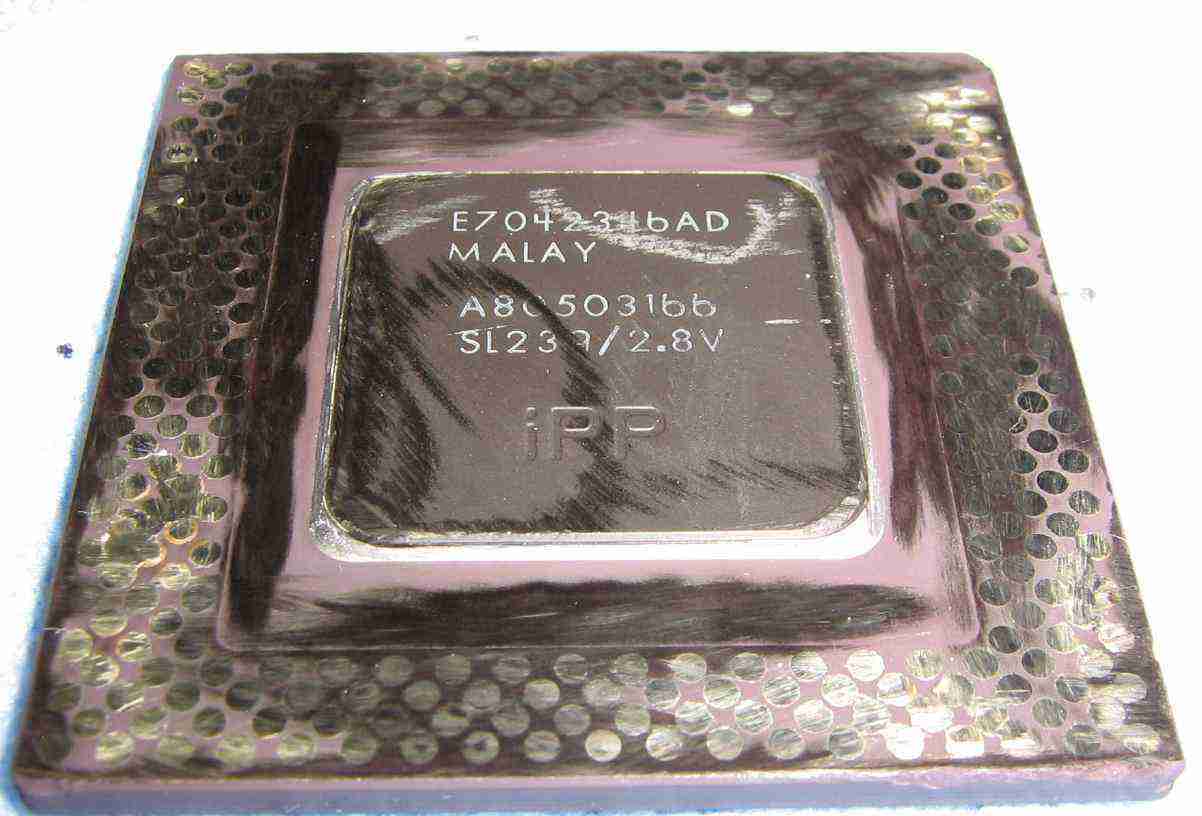

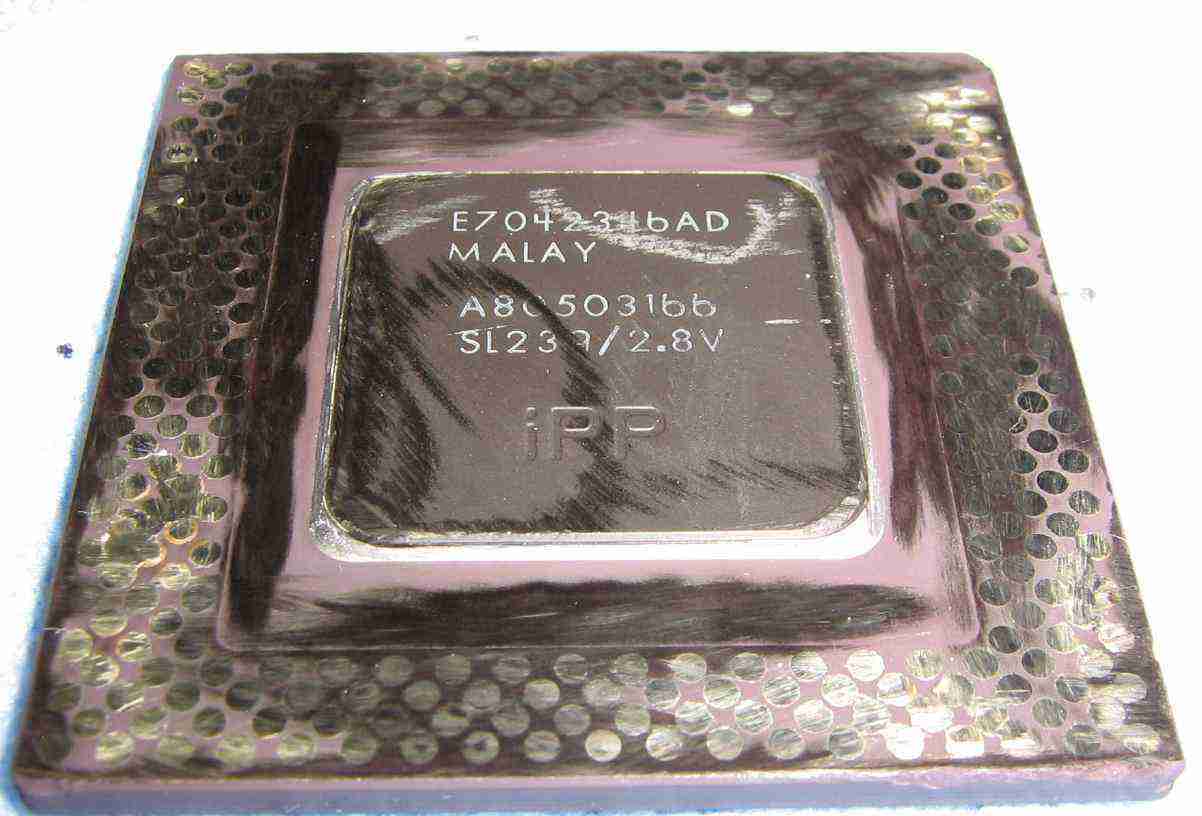

Overview. Four hard drive platters are on the left, and several ceramic packaged CPUs and integrated circuits are on the right. The CPUs are old Intel Pentiums and 486s. These seem to be the best choice, as their ceramic cases are physically larger.

Close up of the CERDIP integrated circuits. You'll need to scarf up old circuit boards at ham radio swapfests to get a large assortment of CERDIP integrated circuits. I found old AT&T telecom circuit boards to be filled with them.

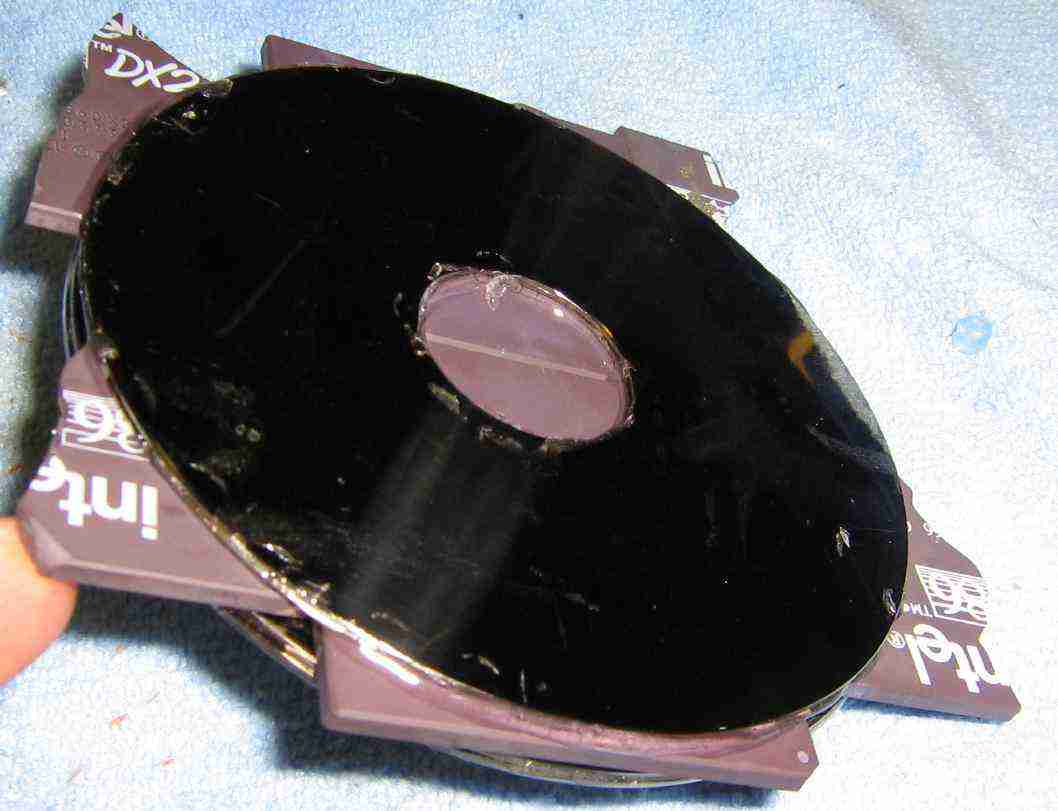

Start like we did in the last issue by epoxying two hard drive platters together. Also do this with the other two platters. The idea is to sandwich the ceramics between the two new dual-platters.

You'll need to grind down the metal pins on the CPUs and integrated circuits. Use an angle grinder with an abrasive wheel attachment. Don't push down too hard, or the CPU will snap in half.

Intel Pentium CPU with the pins ground down. You may want to also grind down the little brazed "cap" that protects the actual CPU. This is the high spot in the middle with the letters printed on it. This will also help the CPU to sit flat when epoxied to the drive platters.

You can snap the CPU into smaller pieces to fill the platters. You'll want to grind down any sharp points when used for "real world" applications.

Epoxy everything together like so. Total weight for this plate was 6.15 ounces.

Close up view. You'll want to make sure that the ceramic cases are all level. That will be a problem if you mix and match CPUs and integrated circuits. Grinding down the sharp points is also a very good idea, but will take awhile.

Notes & Links