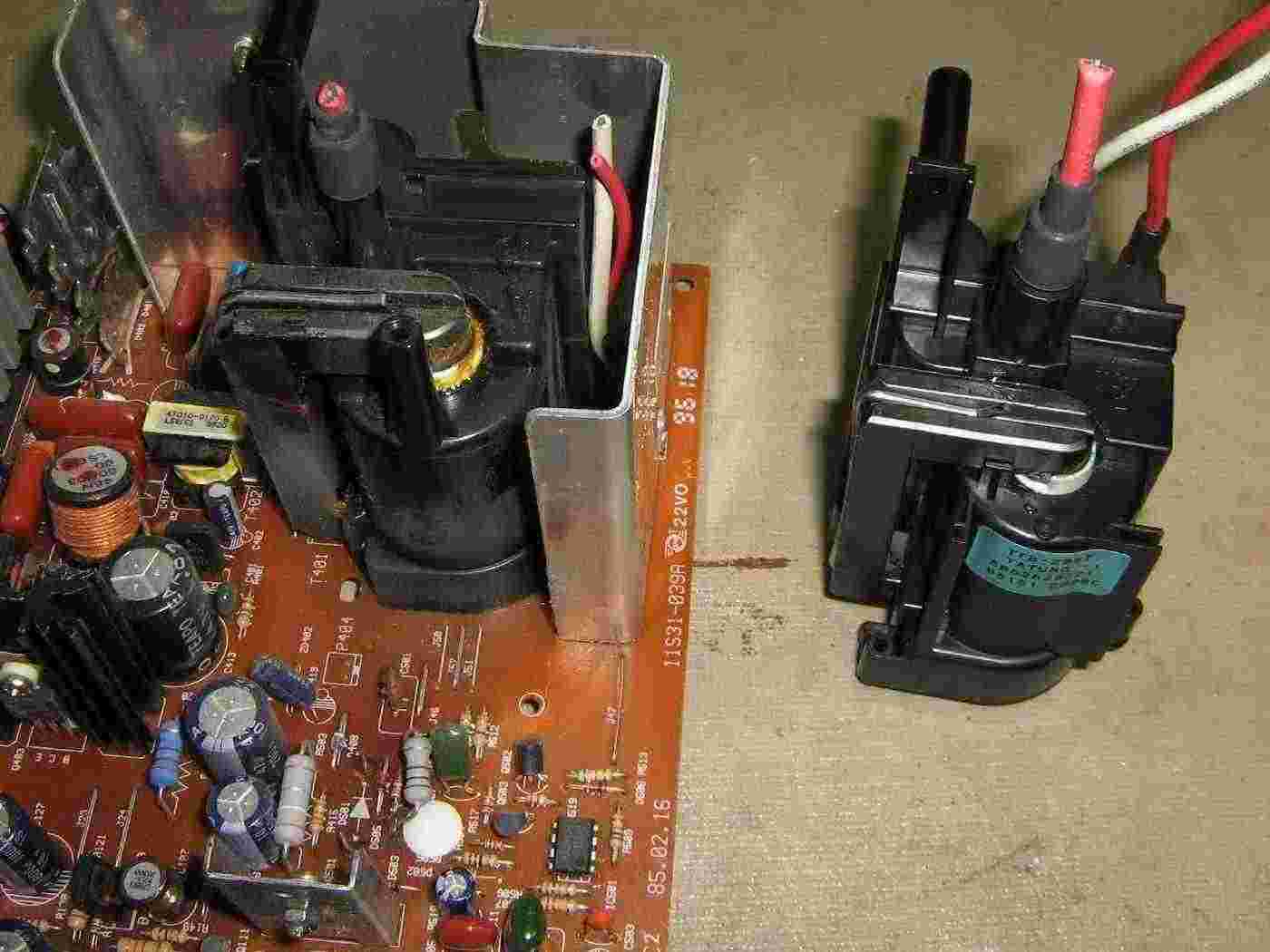

The high-voltage "flyback" switching power supply section in an old CRT-based computer monitor.

The power supply's transformer windings are wrapped around a large ferrite core.

The ferrite core is split into two pieces and may be glued into place.

Remove the retaining clip and use a hot air gun to heat the entire transformer assembly.

Very gently tap the sides of the transformer with a rubber mallet to help loosen the glue. If the ferrite core does break, it is possible to glue the broken pieces back together, but this is not recommended!

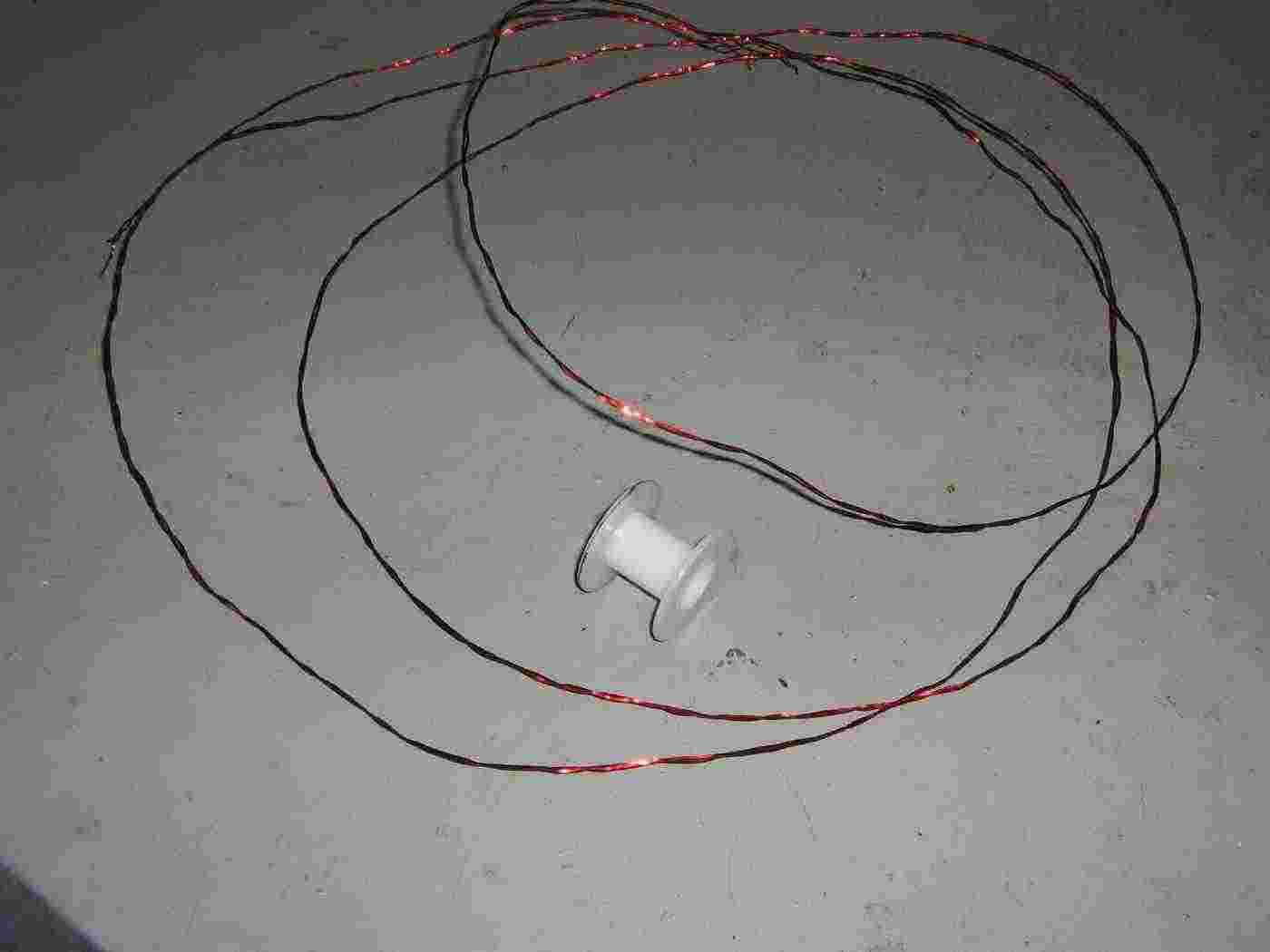

The enameled wire we'll be using and some example ferrite cores on the upper-left.

Believe it or not, you can buy small rolls of enameled wire at hobby stores like Hobby Lobby and Michaels. They should stock different colors of #18 and #20 (and smaller gauges) of enameled wire for use in homemade jewelry and other stupid girl stuff.

For the secondary winding, try to use the largest wire gauge available to help reduce the voltage drop caused by the large current draw from the magnetron's filament.

Try to use different colored wires to help identify each winding.

Bifilar wind (i.e. twist together) two pieces of #18 enameled wire.

I forget the final length you need, but I think it was around 13 feet.

You don't need very many "twists per inch," just loosely twist the two wires together to prevent them from coming apart.

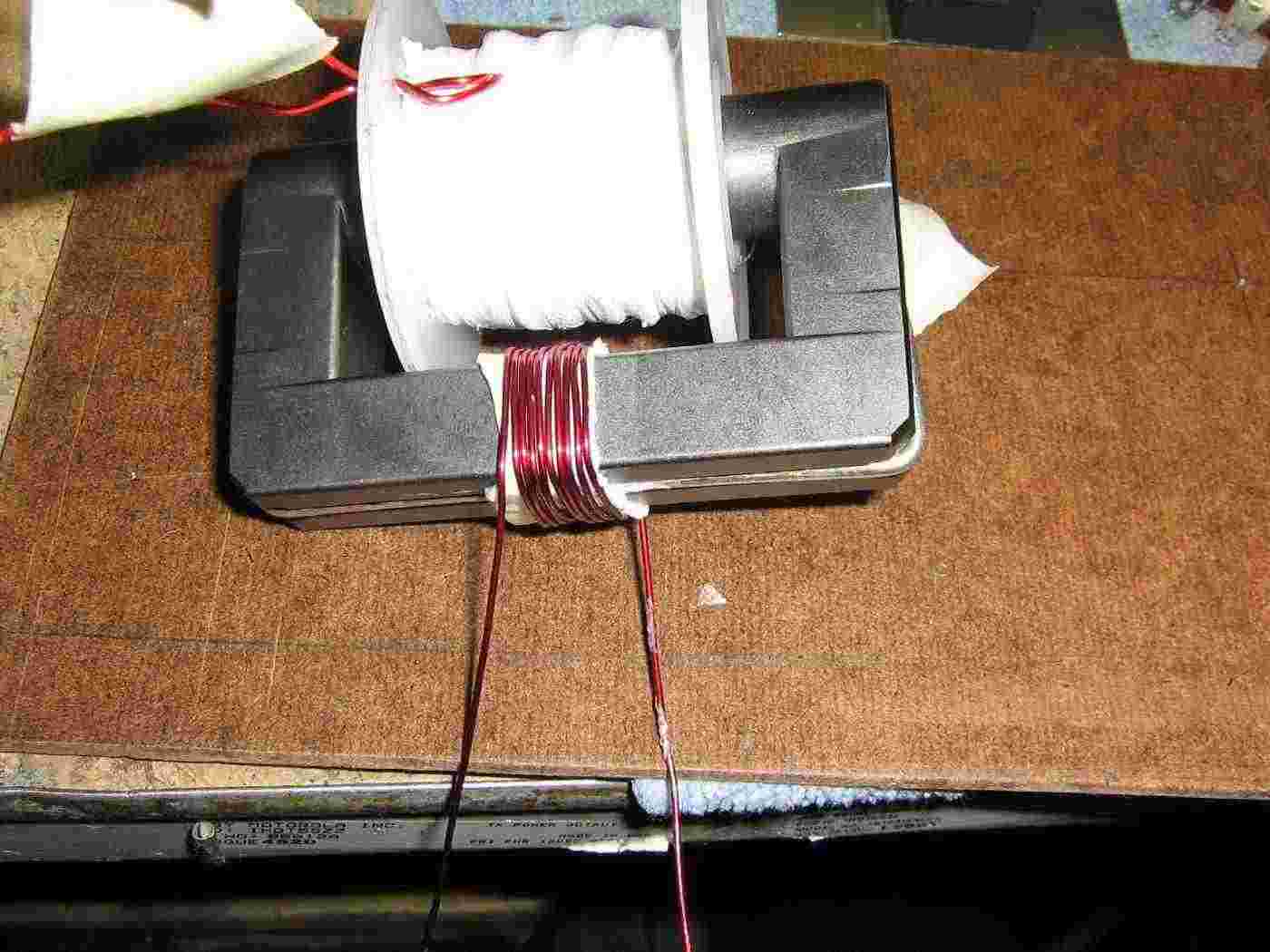

We'll be wrapping this secondary winding on an old plastic bobbin from the pre-tinned #24 bus wire you can buy at Radio Shack (#278-1341).

Wrap a layer of double-sided tape on the plastic bobbin before winding the 40 turns of the secondary to hold the initial windings in place.

When finished, wrap the entire coil with several layers of Teflon plumber's tape.

In order to keep the ferrite core from saturating, you can add a small air gap to one of the core's legs.

I have no idea how large this gap should be (the equations make no sense), so I just used two layers of 3M Super 88 electrical tape.

To secure the secondary coil to the ferrite core, wrap the legs with some double-sided tape.

Add as many layers that are needed to prevent the coil assembly from moving.

Center the coil form around the ferrite core's legs using double-sided tape to fill any gaps.

Be sure to attach the ferrite core's retaining clip and identify and label the each of the wires which make up the primary and secondary windings.

You'll need to watch out for polarity issues when finally connecting the transformer.

Winding the 10 turn primary.

Secure the wires using double-sided tape, then secure them with several layers of Teflon plumber's tape.

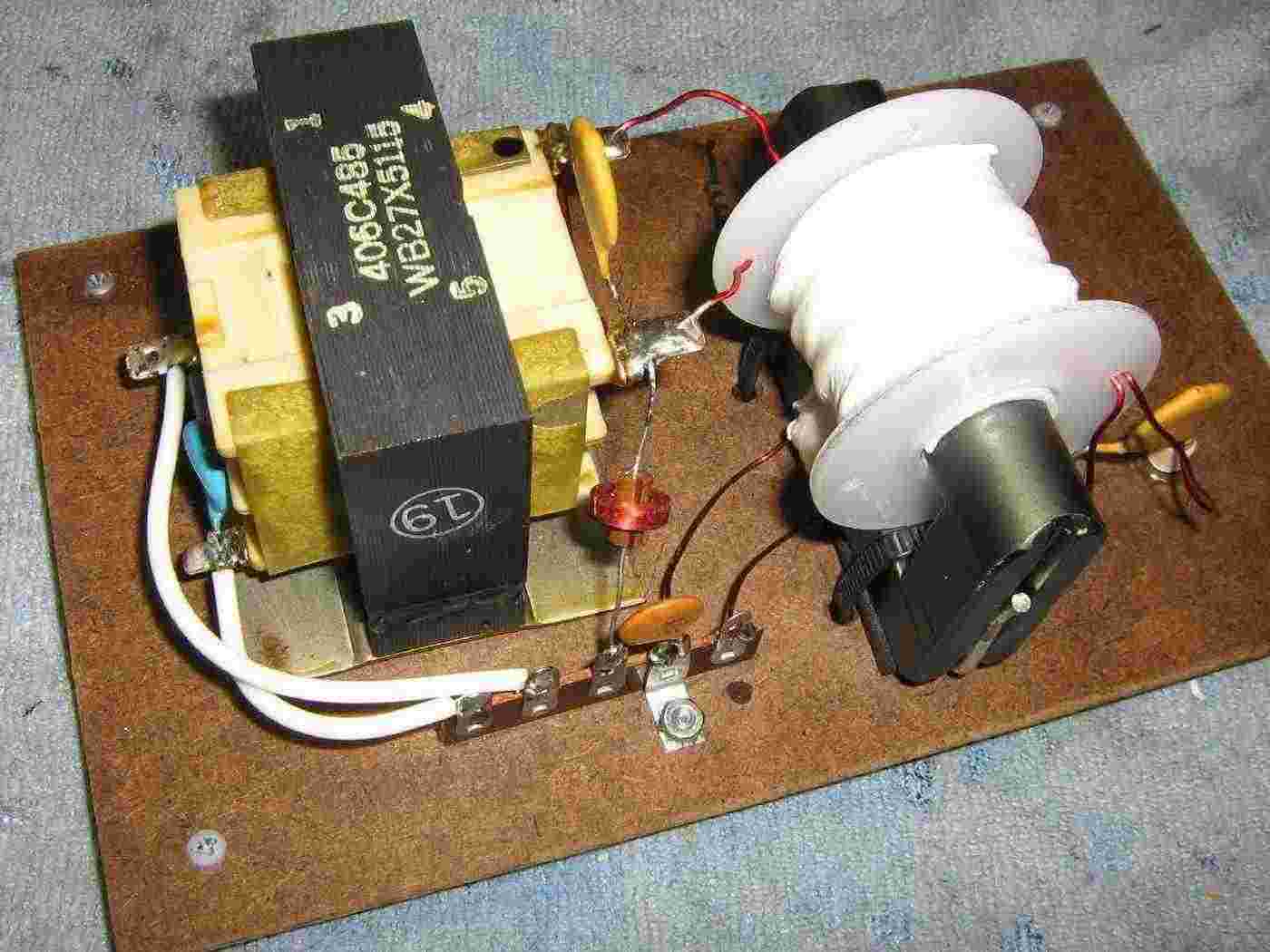

The final inductance measurements for this transformer were:

Turns Wire Gauge Measured Inductance

Primary 10 #20 67 µH

Secondary 40 bifilar #18 620 µH per winding

Completed magnetron pulse transformer with the matching filament transformer.

This entire assembly is mounted on some old clipboard material to help with proper high-voltage isolation. The ferrite core is secured using some pieces of foam and zip-ties.

The 3.3 VAC magnetron filament transformer is on the left, with its 120 VAC primary input connections brought out to some solder terminals (white wires).

The 180 pF capacitors help to "even out" the voltage pulse between the two secondary windings before it is applied to the magnetron.

In the above photo, one of the secondary windings is tapped with a series 1 mH inductor and 0.01 µF capacitor to ground. This forms a little low-pass filter to see if it's possible to measure the magnetron's average current. This is optional and very experimental right now.

I have no idea what ferrite material this transformer core is made out of, but an old issue of QST mentioned some of them use "Ferroxcube 1F19-3C6A" material.

The ferrite deflection yoke from around the neck of an old TV or computer monitor CRT may also work, and can also be found for free.