For Immediate Release

April 29, 1999

STUDYING STEALTH: AIR FORCE BEGINS OPERATION OF WORLD'S LARGEST WIDEBAND BISTATIC IMAGING & RADAR CROSS SECTION TEST FACILITY

The U.S. Air Force will soon begin operation of an upgraded testfacility believed to be the only one of its kind in the world able toconduct wide bandwith bistatic imaging and radar cross section (RCS)measurements of full-sized aircraft.

photo copyrightinformation The mobile radar unit at BICOMS is the world's largestmobile system for measuring radar cross section. It is shown here atHolloman Air Force Base, NM. The mobile radar unit at BICOMS is the world's largestmobile system for measuring radar cross section. It is shown here atHolloman Air Force Base, NM. |

Bistatic measurements are essential to understanding the stealth characteristics of military targets that use shaping as the primary approach to radar cross section reduction (RCSR).

A technical article on the system has been published in the latest issue of the GTRIJournal of Technology.

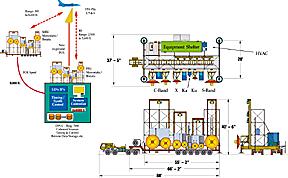

The Bistatic Coherent Measurement System (BICOMS), installed at anoutdoor test facility at HollomanAir Force Base in New Mexico, was designed by researchers at the Georgia Tech Research Institute(GTRI) for the U.S. Air Force 46th Test Group, Radar Target Scattering Division (RATSCAT).

"The Air Force has upgraded its existing fixed-site capability to astate-of-the-art system, and provided a mobile system that is almostidentical to the fixed system," explained Ted L. Lane, GTRI principalresearch scientist and the project's principal investigator. "Themobile system can be moved around on the range, allowing the Air Forceto do bistatic as well as monostatic tests."

The new mobile radar unit -- 40 feet tall, 66 feet long, 37 feetwide and weighing 90 tons -- was built at GTRI's research facility nearAtlanta, disassembled and shipped to RATSCAT and reassembled thereduring the summer of 1998.

The two radar systems are coherent and linked together using fiberoptics for bistatic measurements, but can also operate independently toprovide high speed, simultaneous measurements of two separate targetsunder test. Operating together, the two systems can simultaneouslyproduce bistatic and monostatic data from each radar unit.

"The throughput of the system will be an order of magnitude higherthan it was," Lane said. "Automated features will help bring about amajor reduction in setup time and test time. This will mean asignificant reduction in cost for system operation."

GTRI researchers designed and supervised construction of thetransportable unit, which is the world's largest mobile radar cross section measurement system. They also designed the equipment connectingthe two systems, and the upgrades of the fixed unit. Johnson ControlsWorldwide Services, Inc., will maintain and operate the range for theAir Force.

The fixed radar system can continuously sweep turntable-mounted targets from 1 GHz to 18 GHz and 34 to 36 GHz as they are rotated. Themobile system operates from 2 to 18 GHz, though its capabilities can be expanded because all mechanical systems in place to support Ka band.

photo copyrightinformation Schematic shows major components of the BICOMS systemlocated at Holloman Air Force Base, NM. Schematic shows major components of the BICOMS systemlocated at Holloman Air Force Base, NM. |

On the mobile system, eight radar dishes ranging in diameter from 14inches to 10 feet ensure uniform illumination of targets up to 80 ft inlength at typical ranges of 5,600 ft. On the fixed system, the mobiledishes are duplicated, along with an additional 16-foot dish providedfor the 1-2 GHz band.

On both systems, the antenna positions are computer controlled andprovide an automatic peaking feature to reduce test setup time.

Beyond the expanded capabilities, the system includes automatedcalibration equipment that will improve its efficiency. A key part is aGTRI-designed field probe that provides detailed information in muchless time than earlier systems. The automated field probe (AFP) is acoherent, one way amplitude probe that links the signals from either ofthe radar units to a transmitter located in the field probe via fiberoptics.

"This is a very big improvement that allows us to quantify howuniform the electromagnetic field at the target plane is in real time,"Lane said.

"At a big range like this, efficiency is one of the big drivers," heexplained. "We expect an order of magnitude improvement in the system'sefficiency, which means a reduction in the cost to the range user. Inaddition, improvements in accuracy and traceability are key issuesparticularly important in helping military agencies ensure that systemsmeet specifications and perform as needed."

Difficulties in calibration could affect the accuracy of the data --and performance of the military systems. Calibration must be repeatedduring the day as normal heating and changes in the sun alter conditionsof both the fiber optics and the test range.

"Monostatic radar cross section calibrations are relativelystraightforward," Lane said. "Bistatic calibration over wide bandwidths(1-18 GHz and 34-36 GHz), wide bistatic angles, and especially forcross-polarization, is a real challenge. Monostatic testing cancalibrate against known targets, but no standard exists for bistaticcross-polarization measurements in this test scenario. Since BICOMS isalso a fully polarimetric system, this complicates the calibration. Wehave developed what we believe to be a simple extension of existingtechniques to solve this problem and will be testing this approachduring system validation," he said.

"Since the radars are wide bandwidth systems and the target isrotated during the measurements, both high resolution downrange andcross-range images are produced by each radar for both monostatic andbistatic conditions. This is in addition to total or absolute radarcross section data. Images can be generated with resolution on the orderof 0.5 inches over the 2-18 GHz bandwidth," Lane explained. "Bistaticmeasurements require linking the fixed and mobile radar systems with atwo-mile-long fiber optic cable, allowing synchronization of timing andcontrol as well as phase locking necessary for gathering the coherentdata."

At BICOMS, the mobile system can measure the scattered energy notonly at different angles but also at varying distances from the aircraftunder study. Because it can be moved very close to the targets, it canalso measure near-field effects to understand how factors such as glintaffect the radar signature. This is of particular interest formissile-aircraft engagements.

The project began in 1994 with a review of the Air Force's need forbistatic measurements at RATSCAT. Design and construction began in thesummer of 1997 and involved five subcontractors. The mobile system wasshipped to New Mexico in May 1998 and the fixed system beganinstallation in June 1998. The upgraded facility is scheduled foroperation in May 1999.

RESEARCH NEWS &PUBLICATIONS OFFICE

Georgia Institute of Technology

430Tenth Street, N.W., Suite N-116

Atlanta, Georgia 30318 USA

MEDIA RELATIONS CONTACTS:

John Toon (404-894-6986);

E-mail: john.toon@edi.gatech.edu;FAX: (404-894-1826) or

Jane Sanders (404-894-2214) (770-975-1395);

E-mail: jane.sanders@edi.gatech.edu.

TECHNICAL INFORMATION:

Ted Lane (770-528-7682); E-mail:ted.lane@gtri.gatech.edu).

WRITER: John Toon

PHOTO COPYRIGHT INFORMATION:Photographs and graphics are copyrighted by the Georgia Tech ResearchCorporation and may be freely used by the news media with credit to theGeorgia Institute of Technology. The photographer for the BICOMS imageDavid Asbell. The illustrator producing the BICOMS schematic is EverettHullum.

Latest New;s Research News Research Horizons Georgia Tech Research Institute Georgia Tech ![]()

Send questions and comments to Webmaster@gtri.gatech.edu

Last updated: April 29, 1999