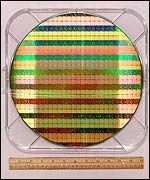

Chip expected to enter mass production next year |

In Silicon Valley

Engineers have crossed a symbolic barrier with a new way to make microchips with transistors that are a thousand times smaller than the width of a human hair or as small as a flu virus.

The 90-nanometre width is regarded as a major milestone because scientists believe it will eventually lead to the production of transistors with atomic level dimensions.

The industry's largest chip maker Intel is at the forefront in manufacturing the world's smallest commercial transistors, giving it a leading edge in the production of semiconductors that run everything from mainframe computers to mobile phones.

But eagerly snapping at the chip giant's heels are competitors like IBM, Advanced Micro Devices and Texas Instruments.

Intelligent machines

The Silicon Valley company says it will reach mass production with the 90-nanometre chip-making process, code-named Prescott, in the second half of next year.

One nanometre is a billionth of a metre, or a millionth of a millimetre.

We want to make our microprocessors as

intelligent as possible because then you can do a lot more with them

|

| Manny Vara, Intel |

"We have been developing the 90-nanometre process for several years and we've seen some significant results and are on target to start producing microprocessors on that technology for sale next year."

Chips typically have millions of transistors, so making them smaller allows more of them to be laid down in the same space and enables the chip to operate faster because electrical signals have a shorter distance to travel.

Intel spokesman Manny Vara said: "The more transistors you have in a chip, the more intelligence you have.

"We want to make our microprocessors as intelligent as possible because then you can do a lot more with them."

He envisages smarter devices that can, for example, translate English into a foreign language in real-time or mobile phones that let you watch a movie with a quality picture and sound.

Mr Vara also predicts an era of "clever computers" that will do things like your shopping online for you by merely showing it a photograph of the item you want, instead of you having to laboriously surf individual websites.

He said most of the products we use today could be likened to a VW Beetle in terms of speed but with the 90-nanometre process, they will be turned into Ferraris.

Smaller, faster

The new process spearheaded by Intel packs two and a half times more transistors into a given space. It relies on four innovations to produce these smaller, faster and more intelligent chips that gobble up less power.

A plant in Oregon is already turning out chips with 90 nanometre wide components using strained or stretched silicon, the foundation for all chips, so that signals run faster across the chip.

90-nanometre width regarded as a major milestone

90-nanometre width regarded as a major milestone |

The exclusive use of copper to connect the transistors is the third major step because it is a better conductor that aluminium.

And the final process is a carbon-based wire insulator that helps reduce power consumption by cutting down on the drag on signal speeds.

Rob Willoner said: "The big benefit is that the transistors are smaller so that they can run faster and that allows us to crank up the speed.

"For example we are about to introduce the 3 gigahertz Pentium. That's three billion switches per second and it wasn't so long ago we were in the tens of megahertz which was tens of millions of switches," he said.

"So we are roughly doubling our microprocessor speeds and the number of transistors on a chip every other year."

Chips currently in commercial production are generally 130-nanometres to 180 nanometres wide. Thinner circuitry achieves the holy grail of making each separate chip cheaper to produce, faster and more energy efficient.

Big business

In this high stakes game, the company that gets their goods on the shelf first is the one that can clean up.

Intel is investing $12.5bn in new manufacturing technologies at a time when the pockets of other players are not so deep.

"Historically the companies that invested in the downturn are the ones that benefited in the long run," said analyst Dan Hutcheson of VLSI research in San Jose.

The speed of progress is in line with Gordon Moore's 1965 prediction - Moore's Law - that the number of transistors on a chip will double every 18 months or so.

In that same year, it was possible to put 30 transistors on a single chip. By 2010, Intel confidently predicts it will be putting 10 billion transistors on a chip.